white cement mortar ceramic tile joint filler,other names:cement based tile gap filler,tile grout

shape:ready mixed powder,color:grey,black,white or colored

main materials:cement,sand,synthetic resin,special additives etc.

Cellulose Ether | Stone Statue | Tombstone | Slate |

Waterproof Series | Indoor Terrace | Mortar | Wall Putty |

Tile Grout | Adhesive | Interface Treating Agent |

25 kgs per bag,24 tons per 20ft. container.

1,we are glad to provide you with free sample 2,we'd like to provide you with professional technic assistance 3,customized products is welcome

4,OEM is welcome

Description

white cement mortar ceramic tile joint filler,other name:crack filler,tile grout

Technical performance

1,moldproof 2,waterproof,crack resistant 3,weather resistance

4,easy to use

Scope of use

Used for filling gaps of wall and floor ceramic tiles,mosaic tiles,porcelain tiles,stones etc.,both for indoor and outdoor use.

Base Surface Preparation

The base surface should have no dust or oil stain,it should be wetted slightly if it is too dry.

Application

1, put the grout into clean clear water and stir until it becomes even thick paste to use.

Mixing ratio of grout to water:25kgs:5.5-6.5kgs

2, apply the grout by rubber drawknife,remove the spare grout on the surface,the usage depends on the width and depth of brickwork joint,calculating method: KG/M2=[(L+W)/(L+W)] X JD X JW X 1.7 (L=length of brick,W=width of brick,JD=thickness of brick,JW=width of brickwork joint.

Please note

1.The construction temperature is 5°C-35°C,

don’t construct in rainy day or under the blazing sun to avoid grout become whitening.

2.don’t walk on the tiles if it is jointed within 24 hours,please brush protection agent first if the tiles are porous.

3.This product contains alkali, please becareful when use it.

Storage and packing

This product can be stored for 9 months under seal in cool and dry place.

packing:25kgs per bag,24 tons per 20ft. container.

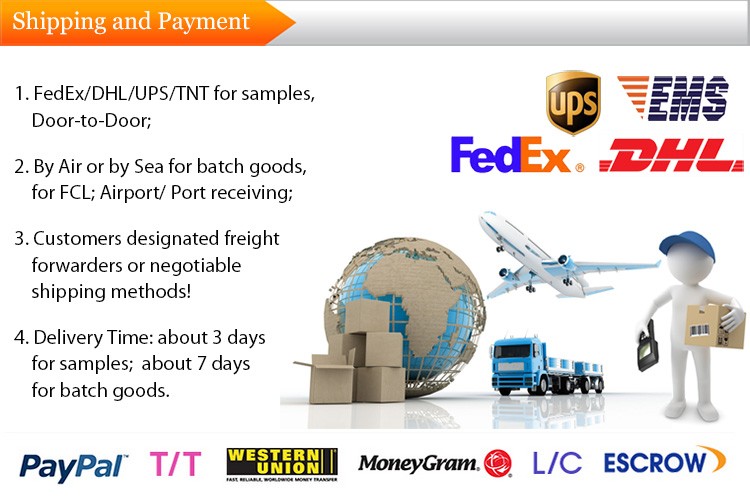

Payment Terms:L/C,T/T.

Delivery time:4 days after the receipt of deposit.